Laboratory Center of Koncar Electrical Engineering Institute

+385 1 3667 302 +385 1 3667 306 lab@koncar-institut.hr Visit website

Fallerovo šetalište 22

Zagreb, 10000

Croatia

Overview

The Laboratory Center is approved to perform testing by DEWA, TRANSCO and SEC.

Key Contact Personnel:

Dalibor Filipovic-Grcic, CEO dfilipovic@koncar-institut.hr

Ivan Novko, Head of HV Lab.inovko@koncar-institut.hr

Daniel Klobučar, Head of HP Lab.dklobucar@koncar-institut.hr

Certification Department scert@koncar-institut.hr

Year Founded:

HV Lab: 1955

HP Lab: 1969

Total Number of Employees: 75

Major Export Markets Served: Europe, Middle East, Turkey.

Services

High Voltage Laboratory

Number of Employees in High Voltage Laboratory: 16

Dimension of Main Test Hall: 35 x 30 x 28 m

Dimension of Secondary Test Hall: 23 x 19 x 15 m; 180 x 22,5 x 12 m

Dielectric Testing Facilities:

| Max. Voltage / Current | |

| Impulse Testing: | |

| Lightning Impulse | 3000 kV |

| Switching Impulse (Dry) | 1700 kV |

| Switching Impulse (Wet) | 1700 kV |

| A.C. Testing: | |

| Dry / Wet | 1200/1200 kV |

| Partial Discharge & RIV Testing: | 1200 kV |

| Capacitance & Tan ∂ Testing: | 800 kV |

| DC Testing | 1200 kV |

| DC Cable Testing | up to U0= 550kV |

Pollution Testing:

| Standards | A.C. Voltage | Max D.C. Voltage | |

| Salt Fog Steam Fog |

IEC 60507 IEC 62217 (1000 h) IEC 60099-4 IEC 61442 |

500 kV | 300 kV |

| 5000 h Multiple stress test | IEC TR 62730 | 72 kV | 50 kV |

Bushing – Type tests on bushings in accordance with IEC 60137, IEEE C57.19.00 and GOST R 55187:

Dielectric tests, Thermal stability test, Temperature rise test, Cantilever tests, Tightness tests, Climatic tests

OPGW wires – Type test according to IEEE Std 1138; IEC 60794-4-10 ( Lightning Arc test)

Cables – Type tests in accordance with IEC 60502-2, IEC 60840, IEC 62067, IEC 61442 HD 620 S2:

Electrical and non-electrical tests

Overhead line conductors – Type test according to IEC and IEEE standards

Insulators – Type tests in accordance with IEC 60383-1 and 60383-2, RIV and corona measurement in accordance with IEC 60437, CISPR 18-2, IEC 61284

Instrument Transformers – Type tests in accordance with IEC 61869-1; IEC 61869-2; IEC 61869-3; IEC 61869-4, IEC 61869-5, GOST 7746, GOST 1983:

Dielectric tests, Temperature rise test, Mechanical tests, Short-circuit tests,

Ferro-resonance test, Transmitted overvoltage test, Transient response test,

Accuracy class test.

Shunt Capacitors – Type tests in accordance with IEC 60871-1; IEC 60871-2; IEC 60871-4

Dielectric tests, Thermal stability tests, Overvoltage test, Ageing test

Power Transformer – Type tests according to IEC 60076-1; IEC 60076-2; IEC 60076-3, IEC 60076-5, IEC 60076-10:

Dielectric tests, Routine tests, Temperature rise test, Short-circuit tests, Sound level tests

Switchgear – Dielectric type tests according to IEC 62271-1; IEC 62271-100; IEC 62271-101; IEC 62271-102;

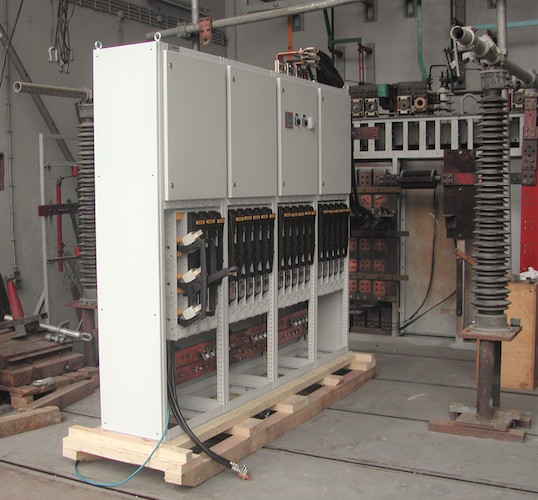

High Power Laboratory

Total Number of Employees in The High Power Laboratory: 4

Dimensions of Main Test Hall:

• Hall for temperature-rise test: 11 x 6 x 7.5,

• Hall for short-circuit test: 7 x 6 x 7.5

Kind of Power Source for the HP Laboratory:

Temperature-rise test: regulating transformer 750 V – 400 A

Short-circuit test: 30 kV, 50 Hz from distribution network

DC source: up to 1000 VDC, 630 kVA

Possible Power Frequency:

Max MVA: 72 Max. kV: 20 Max. kA & Duration: 67 kA; 1s

Electrical Tests: LV dielectric tests up to 5 kV, 50 Hz

Heat Run Tests: Busbars up to 12 kA, 50 Hz; MV/LV cabinets up to 4 kA, transformers up to 2 MVA; 100 thermocouples measurement simultaneously.

Other Types of High Power Tests Offered:

Short circuit tests: three phase up to 40 kA – duration 3s; up to 67 kA duration 1s one phase: up to 32 kA – duration 3s, up to 120 kA duration 0.1 s power transformers up to 2 MVA, 6%, up to 20 kV primary voltage

Low voltage make – break tests:

75 kA@240-420-550 V, 50 Hz; 30 kA@725-1000 V, 50 Hz. Fuse testing: I1 up to 120 kA@550V

High Current Test Facilities & Capabilities:

Main power source: 30 kV, 50 Hz from distribution network, short circuit current at entrance to the test facility: 6 kA Transient recorder: 12 channel, input 100 mV – 1000 V, sample rate up to 10 Ms/s

Additional Test Capabilities:

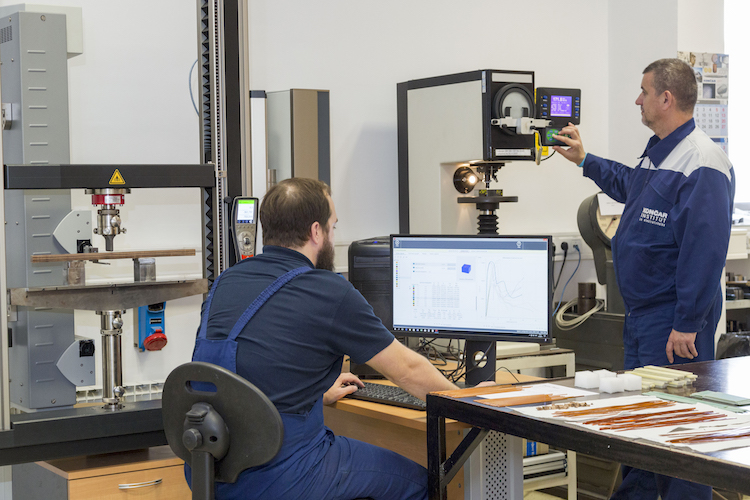

Mechanical Tests (Tensile, Compression, Torsional Tests, Vibrations):

Tensile tests, compression tests, 3 point bending. Universal testing machine 20 kN, 150 kN and 500 kN.

Environmental Tests:

Two climatic chambers: 1,5m3 (-60 to 170°C) and 50m3 (-60 to 100°C), Salt mist chamber: 0,6 m3, IP protection up to IP68; IEC 60529, Protection provided by enclosures (IK); IEC 62262

Acoustic Measurement:

Sound level test for distribution type transformers in the anechoic room (IEC 60076-10), Scope of accreditation:

EN ISO 3744 and EN ISO 3746, Anechoic room volume: 320 m3, Dimensions of anechoic room (in meters – Length x Width x Height): 8×7.4×5.5

Calibration Capabilities:

Reference measuring system for LI, SI, AC and DC, calibrated in DAkkS accredited laboratory.

Accredited calibration service for PD calibrators, factor determination of high voltage dividers and calibration of 50 Hz electric field strength meters.

In-house accredited calibration laboratory for electrical units.

Testing of immunity to vibrations, EMC etc.