Charles Parsons Technology Centre, High Quay, Blyth

Northumberland, NE24 2AZ

UNITED KINGDOM

Overview

Key Contact Personnel:

Stephen Thompson, Business Development Managerstephen.thompson@ore.catapult.org.uk

Alex Neumann, Chief Engineer alex.neumann@ore.catapult.org.uk

Year Founded: HV Lab: 2011

Total Number of Employees: 320

Major Export Markets Served: United Kingdom, Germany, Belgium, France, South Africa, Poland, Australia, Netherlands, with all global manufacturers welcome and supported.

Services

High Voltage Laboratory

Number of Employees in Laboratory: 8

Dimension of Test Hall: 26 m length x 24 m width x 12 m height

Dielectric Testing Facilities

| Max. Volt./Current | Standard/Remarks | |

| Impulse Testing: | ||

| Lightning Impulse | 1200 kV | BSEN, IEC, ANSI, IEEE |

| A.C. Testing: | ||

| Dry | 600 kV | BSEN, IEC, ANSI, IEEE |

| Wet | 600 kV | BSEN, IEC, ANSI, IEEE |

| D.C. Testing: | ||

| Dry | 1 MV | BSEN, IEC, ANSI, IEEE |

| Wet | 1 MV | BSEN, IEC, ANSI, IEEE |

| Partial Discharge& RIV Testing: | 600 kV | BSEN, IEC, ANSI, IEEE |

| Capacitance &Tan ∂ Testing: | 600 kV | BSEN, IEC, ANSI, IEEE |

Other Electrical Testing Facilities at Charles Parsons HV Laboratory

HV/MV Cable Type Testing: UKAS (17025) accredited to perform Impulse, Dielectric (AC and DC), partial discharge, thermal cycling and high current testing carried out on power cables.

Ageing tests: High voltage, high frequency (up to 500Hz), environmental (temperature and humidity) cycling, load cycling

Other tests performed on insulators, arresters, bushings or cable terminations: Thermal stability, temperature rise, cantilever

High Current Test Facilities and Capabilities: 6 kA and 8 kA (3 ph, 50 Hz) test rigs for thermal testing. Tests performed on insulators, arresters, bushings, switchboards, cable breakers, cable systems and all associated equipment.

Transformer Testing: Transformer and reactor single phase AC withstand and impulse testing, including oil analysis.

LV Testing: Certification testing for micro generation and inverter technologies, e.g. ER G83 and ER G59 compliance testing. Custom built LV laboratory to undertake research and development addressing the issues associated with how power generators interact with networks.

• Outdoor test area capable of 350kV AC for prequalification of cable systems and other outdoor tests

• Hydrostatic pressure testing up to 10 bar on cable systems

• Wet thermal cycling (Annex G, IEC 62067/60840) on cable joints

• Fatigue testing on large cable joints (rig bends cable around a former)

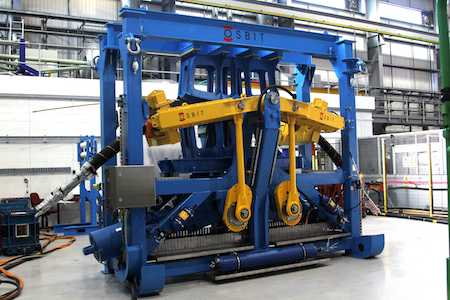

Mechanical handling & dynamic fatigue testing

Industry leading representative fatigue testing of cables and accessories within the standards defined by IEC& Cigre, can be used as part of a full scale type/qualification test.

Associated Services

Forensic Investigations: Failure investigations on switchgear, transformers, bushings, cables, etc.

Chemicals and Materials Analysis: Material investigations, corrosion investigation, including disaster recovery, organic and inorganic analysis, characterization and performance tests on oils, polymeric and composite materials. Analysis techniques include FTIR, DSC, Karl Fischer titration on liquid and solid materials

Environmental Assessment and Testing: Cyclic temperature and humidity exposure, chemical resistance testing.

Consultancy: Power systems including lighting and switching studies, insulation co-ordination fault studies, technical support around material specification and evaluation, market consultations.

Additional Specialist Facilities: Dry dock facilities for saltwater immersion and simulated seabed trialling and testing for MV cable systems and umbilicals.